In printing, there are more variables and options than one can poke a proverbial stick at. Paper type, paper weight, paper colour, offset or digital, run length, colours, size... the list goes on. We can advise on all these decisions in a step by step process to balance your requirements of price, quality and turnaround. Some important steps are listed below.

• Project planning and scheduling

• Graphic design choices, and initial job setup.

• Paper stocks and finishing

• Delivery and logistics

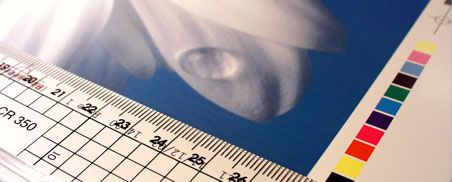

Before a project is under way it's our job to weigh up the advantages and disadvantages of variables such as printing techniques, paper and substrates, ink systems and press sizes. Without having the experience of dealing with an organisation like Paradigm, critical issues to successful production can be overllooked. Some examples are: paper grain direction, apearance of black, overprinting of different colours, image resolution, page and binding margins, production time etc... Specialist options such as foiling, metalics, emobssing, debossing, custom die cutting, unique finishing and special surface finishes are just some of the areas that we have experience in and can advise you of accordingly.

It's not uncommon for larger projects to experience some bumps along the way. Things like last minute artwork revisions, changes to materials or deadlines and shipping/courier delays can put a spanner in the works. We try to use a holistic approach when it comes to managing your job by getting as much information as possible at the start of the project to ensure all bases are covered. Important factors like:

• What will you final product be used for?

• Quality control and processes

• Production facility being used for specific jobs (e.g Geographic location)

• Production and shipping schedules

• Multiple delivery points